With more than 300 employees, KLINGEL medical metal GmbH is one of the leading companies in the sector today. Excellently qualified experts develop, produce and process high-quality precision parts at 103 CNC turning centres, 64 CNC milling centres, 6 wire eroding machines as well as laser systems for marking and welding of assembly groups and special machines.

Whether small or medium series or series production with six-digit numbers of units – KLINGEL medical metal produces high-precision mechanical and precision CNC turned and milled components, wire-eroded components, ready-to-install assembly groups and 3D parts with free-form contours for a variety of industries. If necessary, even short-term production is possible. Packing and logistics included.

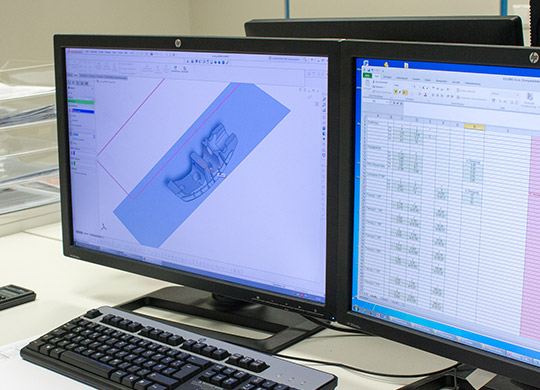

Design to manufacture

Efficient processes thanks to optimized design.

Optimal design with the lowest possible costs: in medical technology as well as in all areas where metal precision is a fundamental requirement, product and process solutions must be planned and implemented in as efficient and sustainable a manner as possible. With our experienced engineering teams who are familiar with the production process as none other, we offer our customers well-founded advice for perfected production and process solutions with regard to design and costs. In addition to experienced technicians, our team also includes young, excellently trained engineering talent.

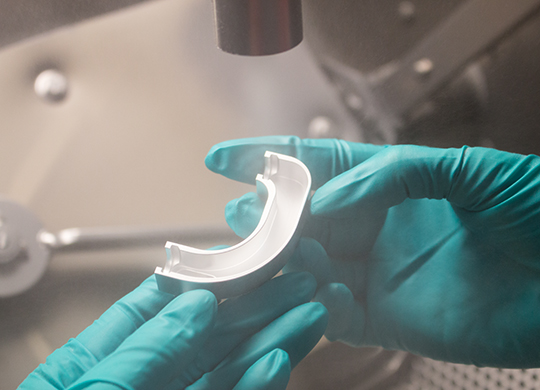

Metal laser sintering (3D printing)

More freedom of design thanks to 3D printing.

In cases in which CNC processing hits its limits and/or erosive processing procedures are not cost-effective for smaller batches, we offer 3D laser sintering in cooperation with our specialized partners as an additive manufacturing process of metal components, which are then processed further by us. Upstream CNC machining for subsequent selective metal laser sintering is also possible.

Metal laser sintering is an industrial 3D printing process used to manufacture in only one process step fully functional metal prototypes and (serial) components with complex 3D surface structures and/or internal ducts and even complete components or assemblies with functional elements such as hinges.

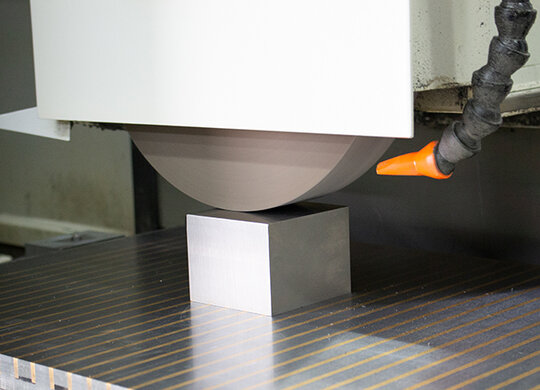

CNC machining

We turn with ease.

The art of precise turning: Klingel medical metal has state-of-the-art machines which are operated by experienced cutting machine operators. Thanks to straight turning machines and turning milling centres, we are able to handle even complex turning tasks very cost-effectively. And this with maximum precision. Our high quality standard for cutting exactly meets the needs of medical technology.

High-tech for high-end products.

In addition to turning, milling is also one of our core competencies. We offer a wide range of milling parts for medical technology and other industries at state-of-the-art CNC processing centres. From the smallest dimensions of 3 mm upwards to large assemblies of 800 x 500 x 800 mm, we are able to create complex geometrics made from titanium, high-alloy stainless steel, aluminium, Inconel, Kovar and Invar.

Precise contours, smooth surfaces.

Quality needs care. Especially when it comes to grinding. Klingel medical metal repeatedly impresses with outstanding surface quality of the metal elements for medical technology. The high art of grinding ensures the finest surfaces and thus impressive technical aesthetics.

We offer our customers services in the area of flat grinding from the smallest size to a maximum component size of 400 x 400 mm.

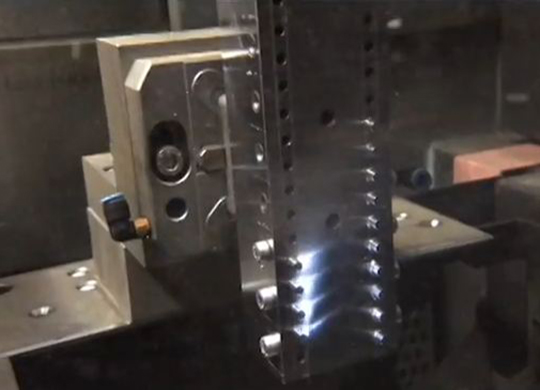

High-precision metalworking by means of spark erosion.

Klingel medical metal integrates both wire eroding and die sinking into the complex process chain of contract manufacturing.

Highly qualified experts develop, manufacture and process high-quality precision components using our die sinking machine from Sodick and the 6 wire eroding machines.

Specifications:

Surface roughness Ra: up to Ra 0.15

Wire diameter: 0.10 mm to 0.30 mm

Standard wire diameter: 0.20 mm

Traverse paths: approx. 370 mm x 270 mm, Z 250 mm

Part height: 160 mm max.

Laser technology

We ensure secure connections.

Knowing exactly what are the specific material characteristics and taking them into consideration is the most important requirement for manufacturing high-end components. This applies in particular to welding technology. We weld a wide range of materials together using the KLINGEL medical metal laser welding technology. The laser pulse used in this technology can be freely modulated. A separate, secured production room with specially trained laser welding staff ensures the required safety in the production process.

Metal marked individually.

Logos, labels, serial numbers, bar code or data matrix code. Even graphics can be applied to metal products by means of CNC laser marking. Labelling by means of laser marking is a modern, flexible and efficient way to label metal parts for medical technology individually. The advantages of laser marking are its high degree of precision and the associated safety and security it provides, for example in the practical use or as a feature to help prevent imitation products and, above all, for secure batch traceability. Laser marking is permanent, contactless and can be performed very quickly. We realize radial and 3-D engravings.

Surface treatment

We make surfaces shine.

For example, we blast surfaces with glass pearls, corundum or ceramics in order to give the exterior surfaces its finish and to produce homogeneous end contours with a matte shine. In addition to metal parts made from different materials, plastic parts are also blasted.

For the perfect finish.

Our slide grinding department has modern high-energy disc finishing systems for wet and dry grinding of metal parts made from various materials. They are finished perfectly in a gentle manner in the drums. In addition to classical deburring by means of larger sanding bodies, shining polishing effects can be achieved with finer granules.

With us, you are always in the pole (-ishing) position.

Our electropolishing machine, which has been approved according to the latest standards of medical technology, puts the finishing touches on medical technology products. It ensures smooth, clean surfaces - down to the most delicate details.<br/> The products are less susceptible to corrosion, can be better sterilized and cleaned, and their visual appearance is improved.<br/> In addition, the component geometry and the frame technology can be constructed in co-operation with the customer at an early stage, optimizing costs and quality. For even more of a start ahead.

Please note that electrochemical polishing is only suitable for materials or parts made from stainless steel. You can find a detailed list of materials here.

Individual labelling with laser technology.

Logos, labels, serial numbers, bar code or data matrix code. Even graphics can be applied to metal products by means of CNC laser marking. Labelling by means of laser marking is a modern, flexible and efficient way to label metal parts for medical technology individually. The advantages of laser marking are its high degree of precision and the associated safety and security it provides, for example in the practical use or as a feature to help prevent imitation products and, above all, for secure batch traceability. Laser marking is permanent, contactless and can be performed very quickly. We realize radial and 3-D engravings.

Surface coating

In the area of surface coating, we offer anodizing and electroplating in co-operation with external partners and integrate these processes seamlessly into our value-added chain.

Cleaning

Cleanliness is next to godliness.

Cleanliness, safety and hygiene are a must for medical technology. For us, they are self-evident. This in particular makes Klingel medical metal a popular manufacturing partner for the medical sector as well as the measuring and control technology. After all, requirements such as freedom from toxins and micro-organisms or the requirements regarding residual metallic particles < 350 µ are standard in our processes. In our fully automated cleaning system, we are working under clean room conditions.

Assembly

We will combine your components in assemblies.

The Klingel medical metal assembly team specializes in the assembly of even the smallest components. For example in the case of our dental ratchets or larger components in the area of operation tables. Added value for our customers: The products can be delivered pre-assembled. Our assembly services are an important part of our service portfolio in medical technology. Many customers value the high efficiency gain for their own business process.

Testing

Testing, one two three...

Complex measurements and tests according to standard specifications ensure reliable quality controls, carried out by our qualified specialist personnel. The excellently equipped test centres and measurement rooms are directly assigned to the various production areas. Our own measuring tool monitoring ensures additional safety.

It is good that quality can be measured.

KLINGEL medical metal has numerous measuring procedures to reliably check the precision and quality of the metal products. They include tactile, optical measuring machines and classical go/no-go gauges. We would be happy to provide you with detailed information on our measurement procedures. Please do not hesitate to contact our quality management representative.

Packaging

Custom-made packaging

The purpose of the packaging of a medical device is to prevent contamination by micro-organisms before the next time it is used and to ensure safe transport. After proper preparation, cleaning and inspection for integrity, we are happy to offer the service of sterile packaging of the metal parts. In this area, we have been working closely with long-term partner companies well-known in the industry – including those within Klingel medical metal group. In addition to the standard solutions for sterile packaging, we are also able to implement extraordinary, individual customer requests. For us, safety is as important as precision.

Inventory management and shipping

Klingel medical metal has developed a logistics offering for customers in the field of medical technology and other industries, which is precisely aligned with the customer's requirements and also includes inventory management. We ensure that the goods are in the right place at the right time.

Benefit from our expertise! We would be happy to advise you personally on our services. Simply Contact us.