PRECISION PARTS FOR MEDICAL TECHNOLOGY: FUNCTIONAL - AESTHETIC - SAFE.

Manufacturing components and assemblies for medical technology makes the highest demands on products and processing. KLINGEL medical metal produces high-quality precision components and custom products. Our highly qualified employees have many years of experience in using a wide range of materials and support you in planning and realizing your individual inquiries. KLINGEL medical metal repeatedly sets new standards in processing metal alloys for medical technology. Sound knowledge and taking into consideration the specific characteristics of the material is the most important requirement for the manufacturing of functional high-end components. Devices and instruments for medical prevention, diagnosis, surgical procedures, therapy and rehabilitation with our precision components provide valuable support for doctors, therapists and patients.

(Cardio-) vascular systems

The heart of our work: Precision.

In cardio-vascular surgery, every single minor detail of the composition and the exact positioning of the parts to be introduced is crucial – it is a source of great peace of mind to know that you can rely on system components that were created with this kind of mindfulness.

Our quality philosophy, which we have practised over many years, allows for the performance of metal work even for the most sensitive medical technology challenges – such as the manufacturing of micro-components for (cardio-) vascular surgeries, for example.

Cardiac pacemakers

WE GIVE THE HEART A HELPING HAND.

The manufacturing of cardiac pacemakers or artificial cardiac valves requires zero-tolerance quality and process reliability. We guarantee both thanks to our zero-error strategy.

Placing the highest standards on accuracy, freedom from burrs and surface condition is a natural part of our responsibility.

Our operations are always state-of-the-art, and we use our years of experience to meet new challenges, going to the boundaries of what is possible.

Micro-components for catheters

Our quality philosophy, which we have practised and refined over many years, allows for the performance of metal work even for the most sensitive medical technology challenges – such as the manufacturing of micro-components for (cardio-) vascular procedures, for example. Placing the highest standards on accuracy, freedom from burrs and surface condition is a natural part of our responsibility.

Dental

Functionality and aesthetics: For the perfect look.

In the field of dental technology, we are not only a reliable OEM manufacturer of standard components of well-known companies, but together with our subsidiary Josef Ganter Feinmechanik in Dauchingen, we are also a successful supplier of our own designs like torque ratchets and their accessories. This is not only because of our quality but also because we represent the whole value-added chain for dental companies. From consultation through planning to sterile packaging. With extensive know-how and the utmost safety by means of certified processes. This guarantees an ideal workflow along your supply chain.

Implant

AESTHETICS REQUIRE PRECISION. AND AN EYE FOR THE BIGGER PICTURE.

We have been producing high-quality dental implants, prosthetics and the matching instruments, torque ratchets, osteotomes and implant drivers for more than 30 years. Our range of services in the dental field also include all products for the CAD/CAM flow. Our state-of-the-art machinery provides the utmost precision. It covers all requirements for the most demanding production: Turning, milling, eroding, grinding, laser welding and laser marking.

Screw-in instruments

FOR THE PERFECT TURN.

In addition to a wide range of standard ratchets, we offer customized designs, including the appropriate tools and wrenches, in cooperation with our subsidiary Josef Ganter Feinmechanik in Dauchingen. In addition to approval as a medical product, their advantages are the individual customer logo, which can be applied by means of laser marking and/or sterilisable ceramic paint. In addition, Josef Ganter is the manufacturer of a one-piece universal torque ratchet which can be processed without dismantling in practice after use.

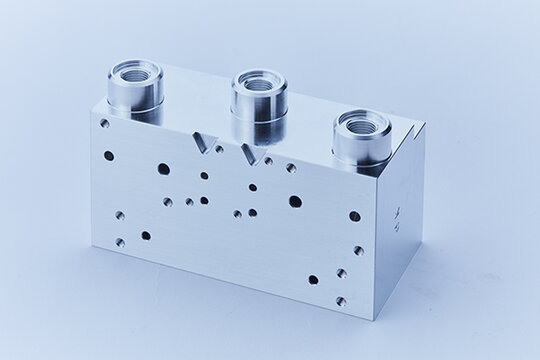

Medical devices

The perfect fit. For the highest standards.

Modern high-tech medical technology only works due to its complex interiors. Whether these are highly complex components for intensive ventilation systems, such as mixing machines and valves or sensor cases for dialysis systems – at Klingel medical metal, everything fulfils the highest standards. The mounting of mechanical assemblies such as operation table systems is also part of our services.

Components for dialysis devices

Dialysis machines help to keep people alive and improve their quality of life. A high reliability of quality and cleanliness are the basic requirements for delivering products and components made from metal for the manufacturing of dialysis devices. KLINGEL medical metal uses the most modern manufacturing technology and its many years of experience with products for dialysis in order to develop innovation and optimize existing techniques together with the customer.

Components for ventilation devices

Minimally invasive systems

Extreme precision. For the innermost parts.

We reliably deliver even complex components in the desired high quality and surface quality from a single source: From turning/milling and flat grinding to the surface finishing by means of electropolishing and cleaning and even to logistics. When using instruments and components in contact with the human body, for example, the pathogen-free application of the components is crucial.

For a perfect finish, Klingel works with one of the most modern electropolishing plants in Europe. Thanks to the integrated modern PLC controls, it is approved according to the current standards of medical technology. Electropolishing puts the final touches on medical technology products or removes material within the scope of micrograms. The result are ideal characteristics of the electropolished parts for sterilisation and cleaning due to their smooth, homogeneous and clean surfaces – even in the most delicate details.

Endoscopy

Our technically and aesthetically sophisticated products and components are successfully used in both standard solutions and highly complex surgical robot systems, e.g. the well-known daVinci system. The products and components for this field are characterized by high precision and impeccable surface quality. They meet the high standards of our OEM partners and medical device manufacturers.

Basic bodies for endoscopes

We are partner of well-known manufacturers of minimally invasive surgery systems and meet their high requirements regarding the surface condition of the components.

Endoscopy components

In order for components to interlock perfectly, to complement each other in terms of functional aspects and to provide a cohesive appearance, knowledge of materials and their processing and application options is of great significance. KLINGEL medical metal has may years of field-tested know-how we can use to achieve just that.

Robot-assisted surgery

Intelligent solutions. For precise surgical procedures.

Again and again, we are able to wow our customers with our wide range of materials, as well as all of our manufacturing, finishing and assembly options, which Klingel medical metal seamlessly combines. At the end of our one-stop shop strategy is the component or assembly ready to be used by the customer, which also has the appearance of being made from one piece. Design, function, safety and economic efficiency are all just right.

The mechanical assistants of robot-assisted systems continue the work when human hands meet their limits at the operating table. And with Klingel medical metal as the OEM partner, medical technology manufacturers redefine the boundaries of what can be achieved in the development and manufacturing of innovative components.

Joints

Due to their joints, the use of medical devices and systems with different peripheral modules can be adjusted flexibly to the respective operating/environmental situation and ergonomically to the operator. And the precision mechanics of robots are also always getting better thanks to ingenious joints. We meet the requirements with respect to surface quality, sturdiness and durability.

Trauma treatment

Supporting the healing process with precision.

During the development and manufacturing of dental implants, we have gained valuable experience that we can successfully apply in the area of trauma – for the production of bone nails, bone plates and screws. When used correctly, they can support and stimulate the healing process.

Surgeons are frequently gushing praise about our high-precision metal parts with the finest surfaces, the highest material quality and precision. Our understanding of precision and safety is a guarantee for sustainably excellent results.

Bone plates

Fractures are rarely immobilized with a cast nowadays, but are rather increasingly fixated with nails and screws. The advantage of the "internal splint": No need to wear a cast for weeks, better healing and only a few symptoms. Bone plates and fixation devices have to comply with a great number of standards and codes in medical technology, since they are used in treatment of complicated fractures, for example. KLINGEL medical metal has been successful for many years in keeping up with the growing requirements and testing methods with regard to biocompatibility, chemical durability and corrosion resistance, stability, flexibility and fatigue behaviour of the material used and its characteristics.

Instruments

Our instruments and tools: For an ideal procedure.

Our calling and area of expertise is highly precise metalworking. We love our trade and manufacture a wide range of instruments for medical technology, using a high degree of technological aesthetics. Our services range from wire cutting, laser welding and surface treatment to the installation of medical technical instruments. For example, Klingel medical metal manufactures:

- Osteotomes

- Implant drivers

- Torque ratchets

- Instruments, among others for knee operations

Hip rasp

For the hip endoprosthesis bed in the medullary canal, the surgeon requires a rasp with the contour of the implant to be placed. KLINGEL medical metal manufactures the instruments as complete processing in a rotation mill centre. Our electropolishing system ensures a perfect surface.

Orthopaedics

The backbone of it all: Our partnership.

Klingel medical metal cooperates with leading providers of innovative product solutions for orthopaedics. We know what is important in implants, endoprostheses, tools and fixators. In extremely sensitive areas, uncompromising precision is required down to the smallest detail. We have made a name for ourselves with medical technological metal works as an OEM manufacturer because we meet even the highest demands regarding precision and freedom from burrs in the use of these components.

Spine

PRECISION IS THE BACKBONE OF SURGERY. AND OF OUR PRODUCTION.

We know what spinal surgery is all about. Working in highly sensitive areas requires uncompromising precision. We have made a name for ourselves with medical technological metal works because we meet even the highest demands regarding precision and freedom from burrs for placing these implants in the region of the spine. For example, KLINGEL medical metal manufactures spinal cages, fixators or pedicle screws, also in a cannuled version, for well-known manufacturers.

Knee

During the procedure for a knee joint endoprosthesis, the defective joint surfaces are removed first, and the bone is then prepared in such a way that the artificial parts of the joint can be anchored firmly. The surgeon does this using special stencils. These help them to make the incisions and place drill holes on the bone in the right place, to remove the bone to the appropriate extent for the implant and to position the prosthesis precisely.

Neurosurgery

Neurosurgery

In the field of neurosurgery, we manufacture parts for head retaining systems, among other things. If you are developing medical instruments and systems to treat diseases, injuries and malformations in the area of the skull, brain and spinal cord, please do not hesitate to contact us and inquire about the possibility of cooperation.

Ophthalmology

Ophthalmology

We manufacture components for optics and instruments for the ophthalmology market.

Operation tables

We manage to hit the sweet spot with your quality.

KLINGEL medical metal’s machinery park and the number of technical aids at its disposal have been growing continuously. Therefore, we are also able to offer products and components for large-scale medical devices. We provide manufacturers of operation tables with precise components made from stainless steel and aluminium up to a size of 800 x 500 x 800 mm.

Components for installations on surgical tables

Our components for surgical tables have to meet the flexible requirements and multi-disciplinary purposes in everyday use. In addition, they should be easy and comfortable to operate in the context of use together with other components and systems as well as with other, partially variable equipment.

ENT

Ear, nose and throat medicine (ENT)

In the field of ENT, we work with partner companies to develop high-quality implants and components to improve hearing ability and hearing acoustics.

Do you have any questions? Would you like to receive a quote or consultation? Simply contact our medical technology specialists – we look forward to hearing from you!